A major international fleet management company needed to optimize processes to better align operations with the company’s strategy. We helped, improving service level agreements (SLA’s) from 70 to 95%+ in all business office departments.

Who:

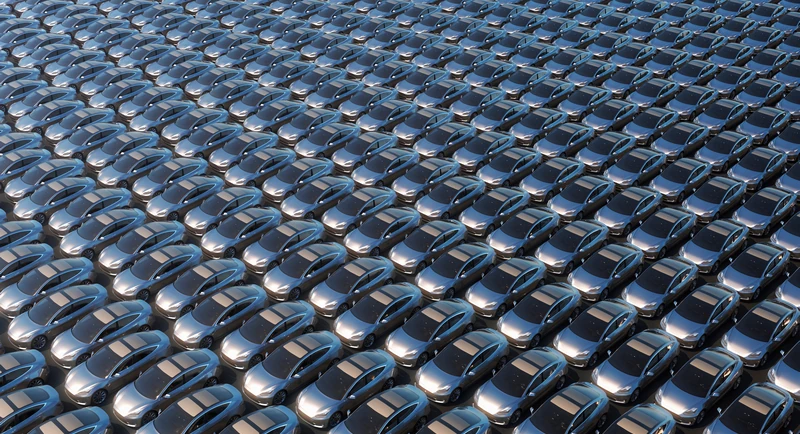

A fleet management company overseeing vehicle fleet performance for corporate clients. The organization is the number two player in a growing market whose customers are both the corporate fleet managers and vehicle drivers. Their operation manages processes related to the life of the leasing contract, from inception to termination.

The Client Ask:

Improve transactional flow and increase capacity, enabling the existing volume of requests to be satisfied without adding additional resources. Optimize business processes associated with both corporate fleet management and auto operations to remove variability.

Attributes at Start of the Project:

At the start of the project the company’s service levels ranged from 60-70%. The operations teams were not able to keep up with the high volumes of transactions leading to long delays, angry customers, and the loss of contract renewals and revenues. Management was under pressure to increase overall efficiency.

The management style was a traditional command and control with a high focus on productivity. There was little employee empowerment and no engagement. Operations teams worked with a permanent sense of urgency. Employee burnout was common leading to a high turnover and loss of tacit knowledge.

How we helped:

We conducted several awareness education sessions on the Lean principles for the company managers; having them share the Why and How Lean would improve operations for their teams and for themselves. With that understanding in place, they then learned key Lean concepts, how to see waste, and the best approaches to address the causes of waste.

This built their confidence and created an optimism that they would be able to chart a course out of their difficulties. They understood their role in supporting team members to improve flows, make activities visible, and establish new roles and responsibilities to improve efficiency and effectiveness.

We worked closely with them and employee teams in cross-functional pilot projects, establishing the principles of visual daily flow management, enhancing the principles of understanding demand, measuring, and scheduling. Pilot results included outputs improved by 50% and improved service levels to 85% on target processes…with positive customer feedback, and a generated sense of satisfaction and positive energy.

In the next phase, we coached managers as they replicated the process and applied the learning to their own departments, establishing targets to improve and identifying projects that would increase throughput and capacity while creating team stability, in line with leadership expectations.

At a later stage, when all managers felt confident in their ability to successfully manage teams, a hoshin kanri session was conducted, establishing a shared vision, and cascading the organization’s overall goals into department goals, identifying additional targets for improvement.

Finally, we mentored an internal improvement team, further enhancing the skills they developed during the earlier phases. This provided the organization with a solid internal CI capability which has allowed them to continue to guide improvement projects and deliver ongoing support to managers and teams.

The Outcome:

Mission accomplished! Optimized operations capabilities, increased capacity, reduction of turnover, and improved customer service reaching service levels between 90 to 97% in an 18-month period.

At the conclusion of the engagement, all departments in operations, plus customer service, legal and finance, were actively engaged in operational excellence.

This engagement started with education, alignment and small projects meant to build confidence and create showcases to get people engaged and on board. It was a very satisfying mission for our team and a very open, trustful, and continuous relationship with our client.

|

What’s keeping you up nights? Tell us about your concerns and we can assist you in your reflections and in achieving similar outcomes. |

Give us a call at (203) 225-0451 or email us at lean@productivityinc.com.